Ground Frame Column Installation

Overview

The Ground Frame Foundation System provides a solid, stable, and efficient foundation that captures and preserves the supporting strength and natural functions of the Earth’s soil and provides a connection to the structure above.

IMPORTANT NOTE:

- Prior to commencing work, all installations must be reviewed by Ground Frame engineering team or the project engineer of record.

- Ensure all permits have been obtained.

- Check for buried utilities, mark on site as per local building codes.

- Have all required tools and equipment outlined below.

- Wear proper safety gear.

Safety Glasses

Ear Protection

Steel Toe Work Boots

Rubber Insulated Gloves

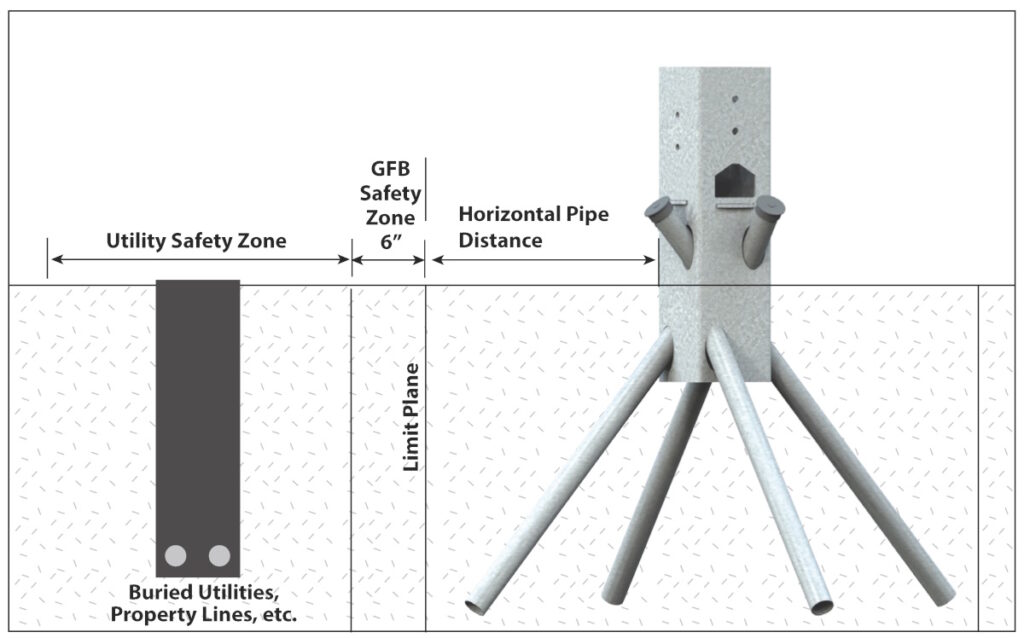

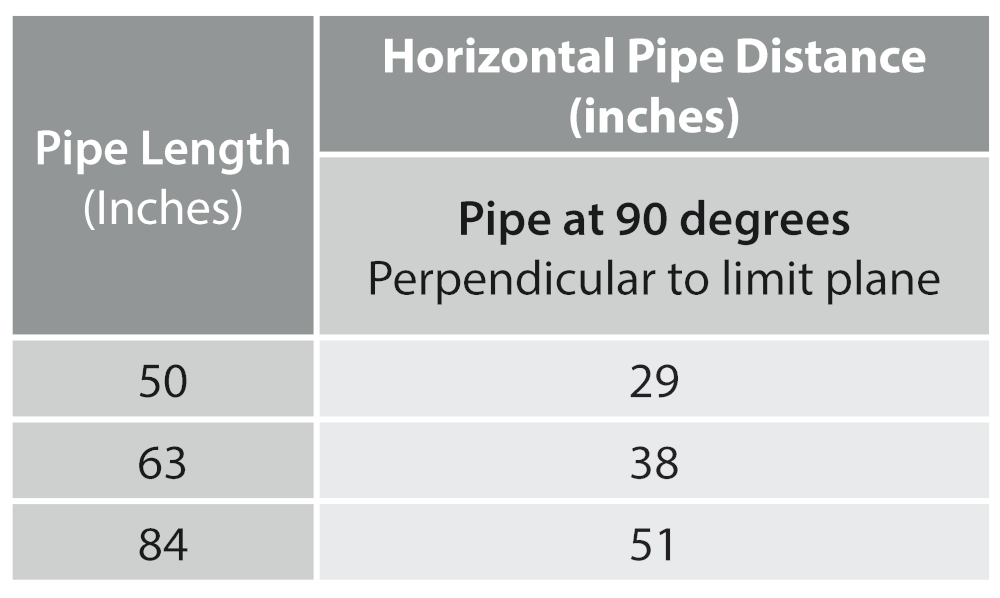

Horizontal Pipe Distance

Measured from horizontal center of anchor bolt to vertical pipe end limit

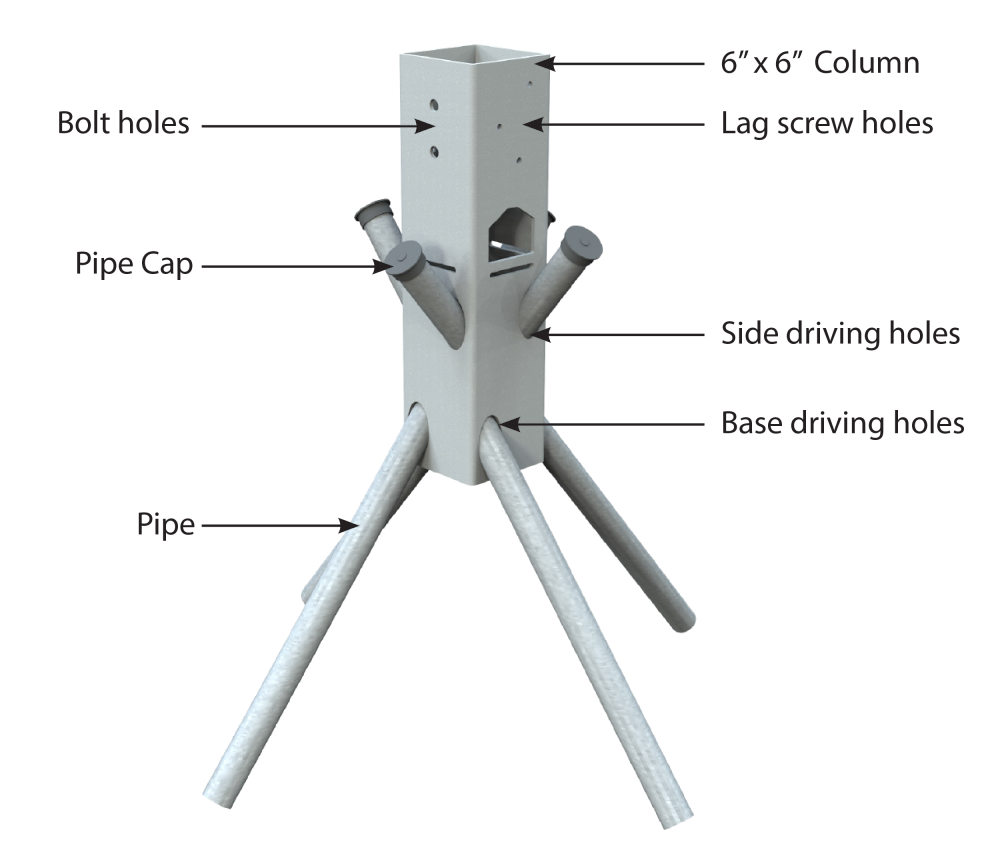

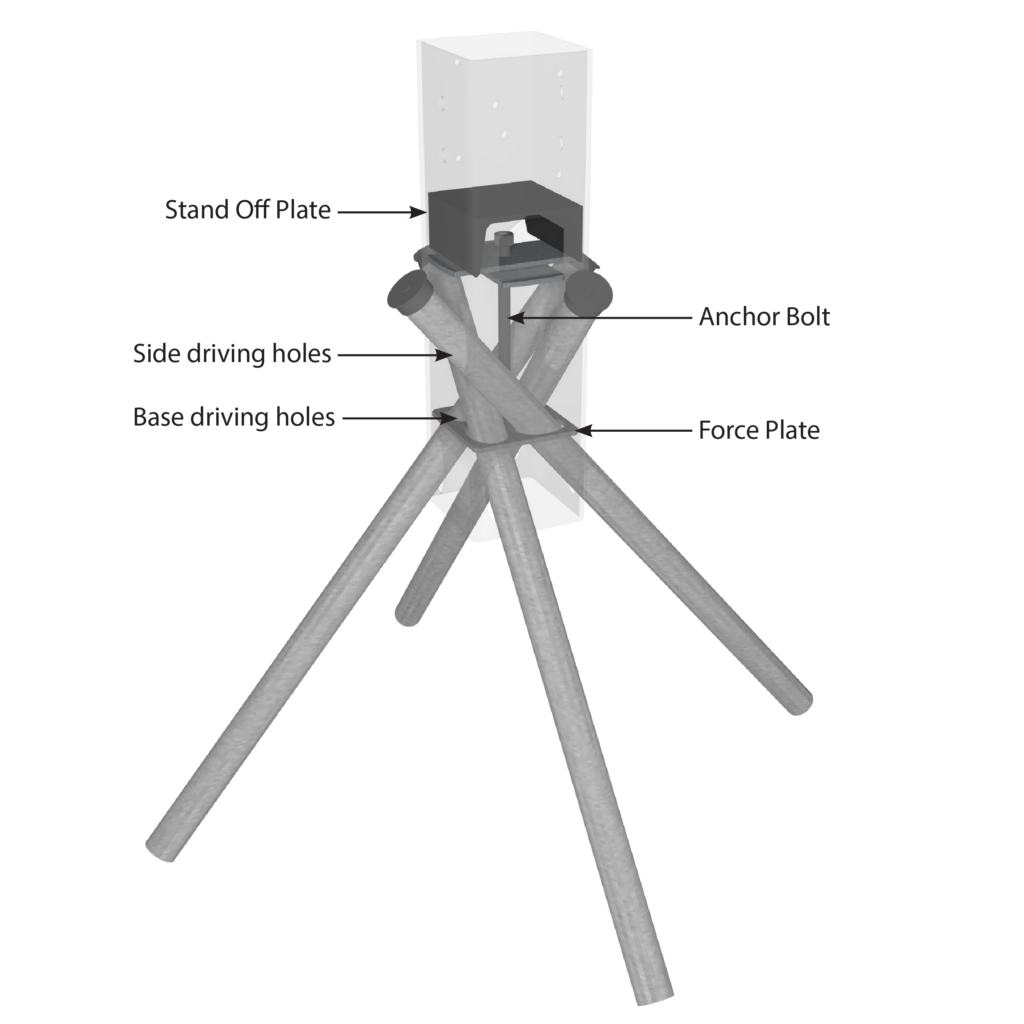

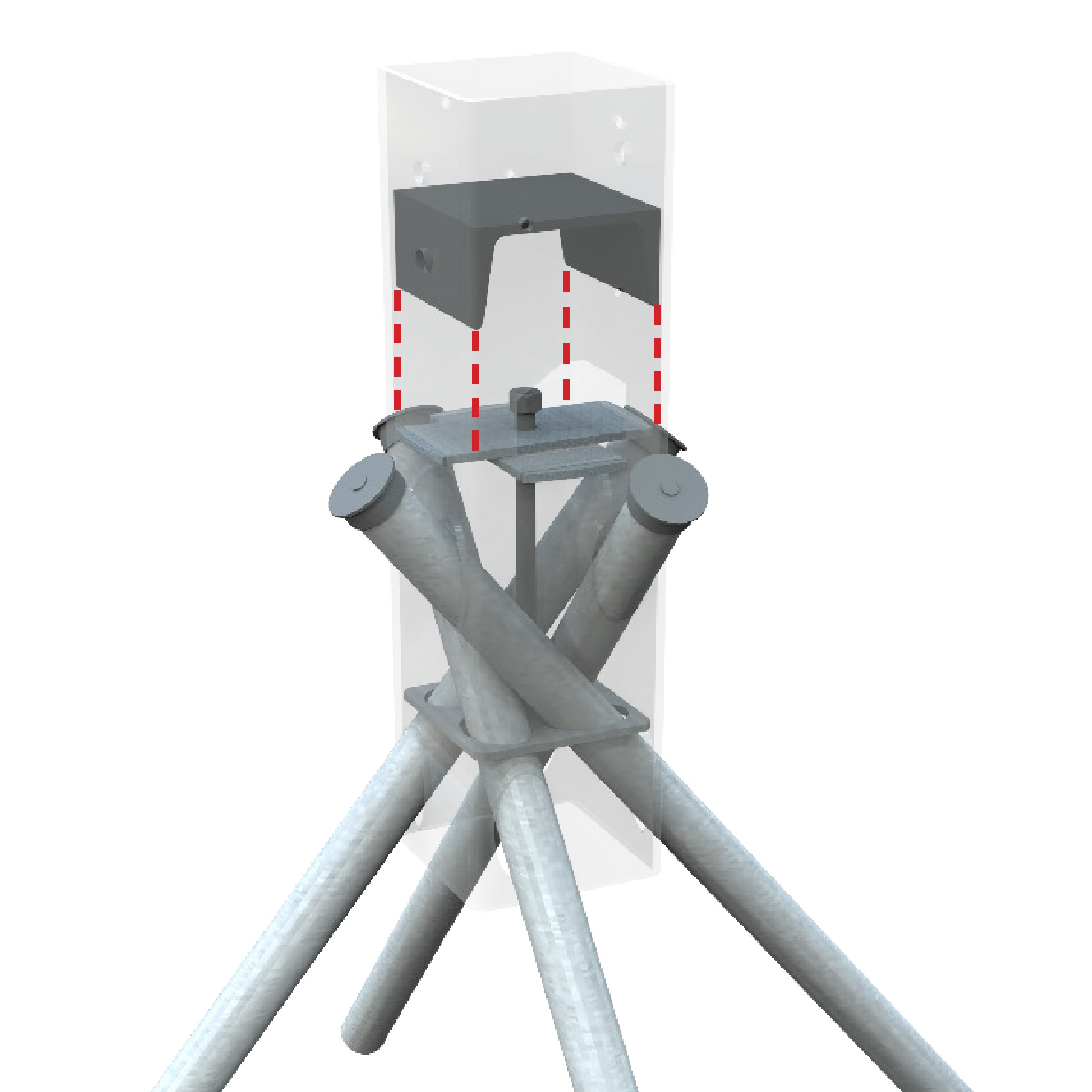

Ground Frame Column (GFC-125) Overview

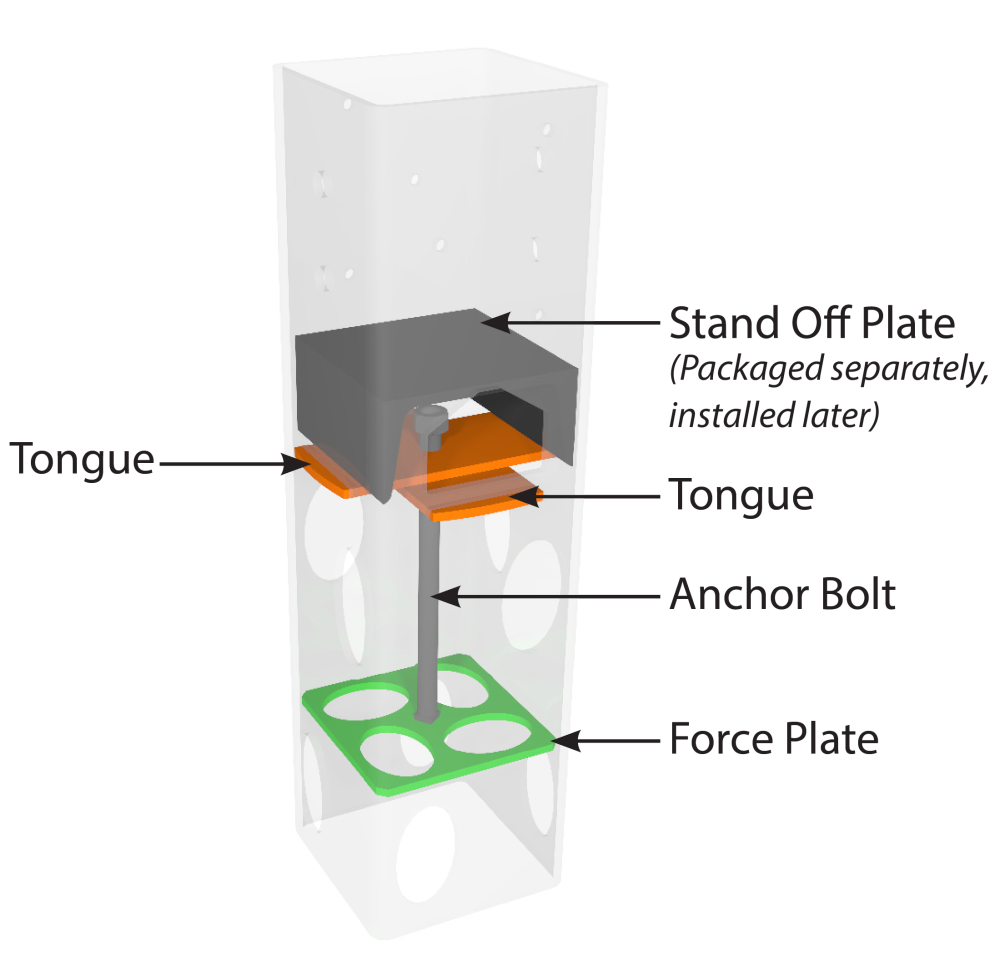

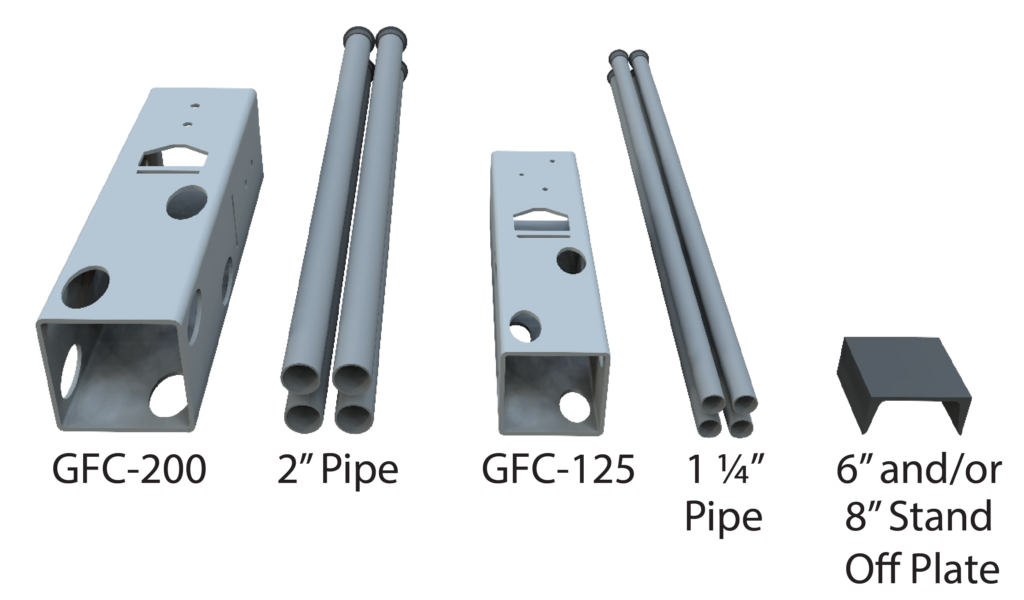

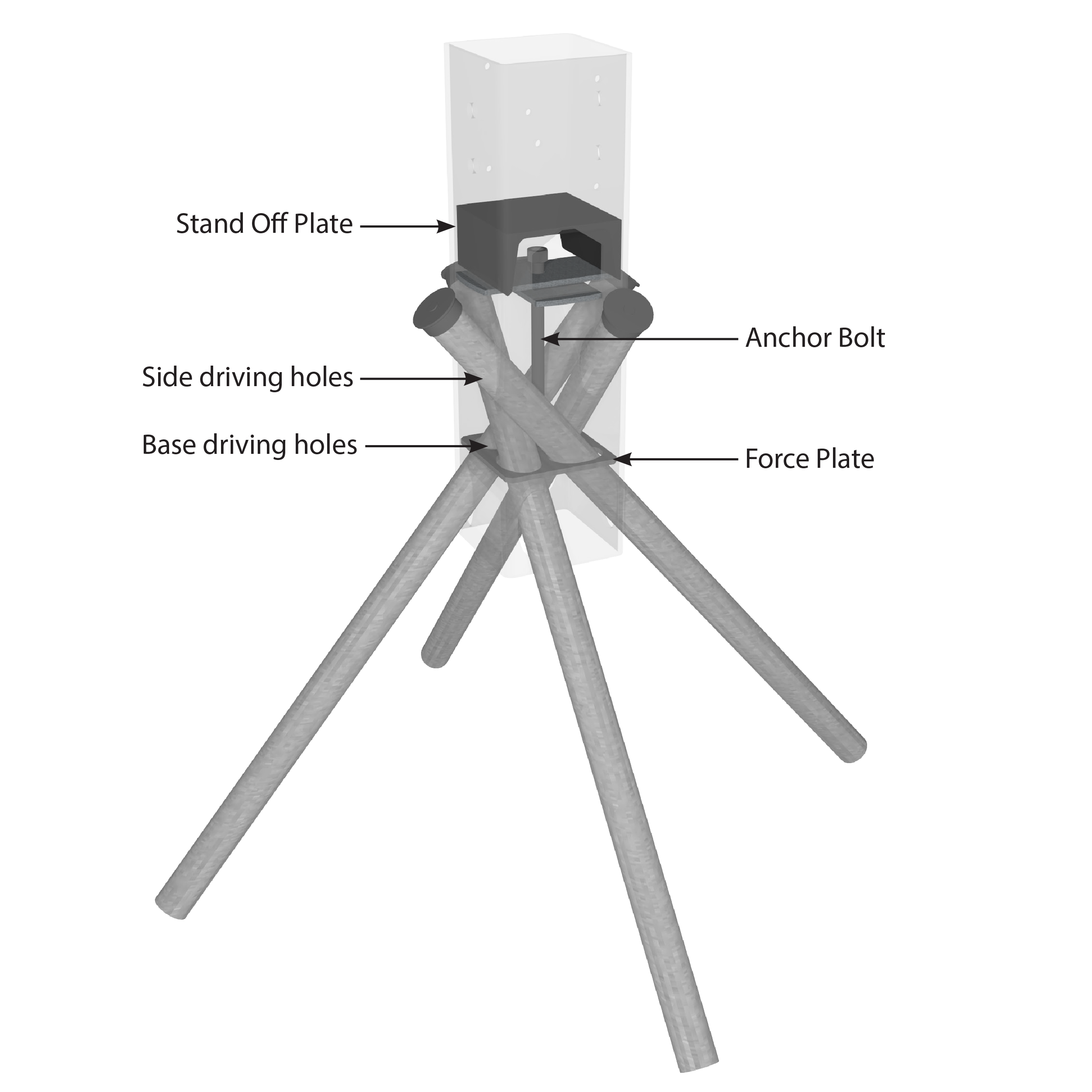

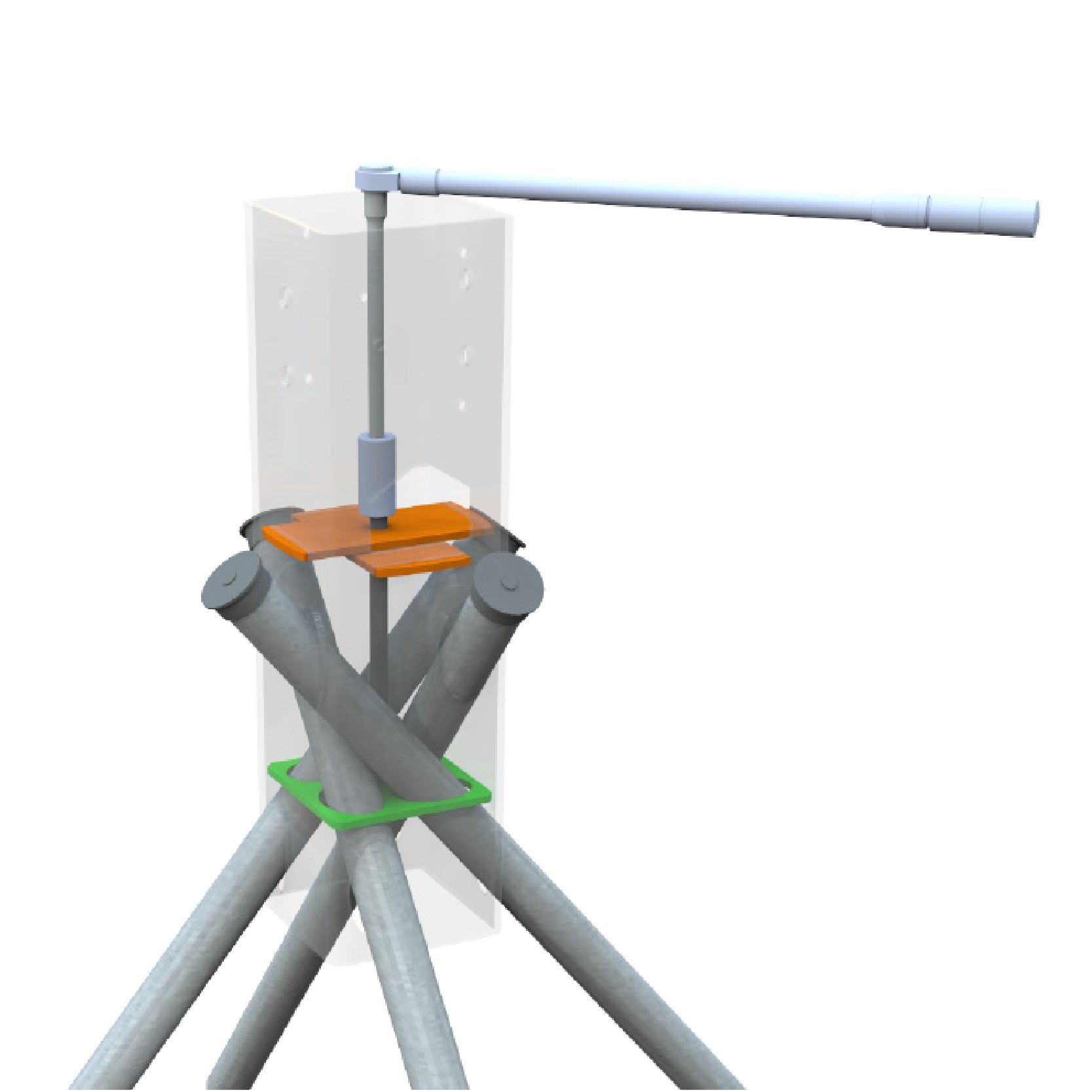

Internal Components for GFC-125 and GFC-200

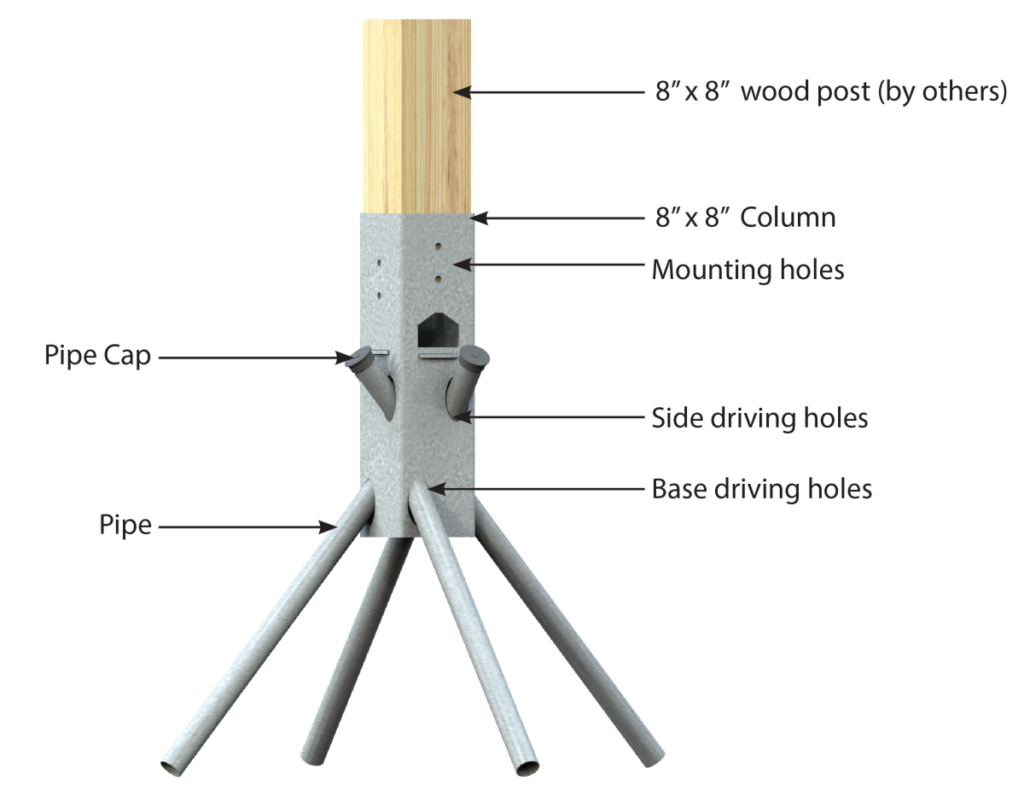

(Parts are colored for visual purposes only, all parts have a galvanized finish)

Ground Frame Column (GFC-200) Overview

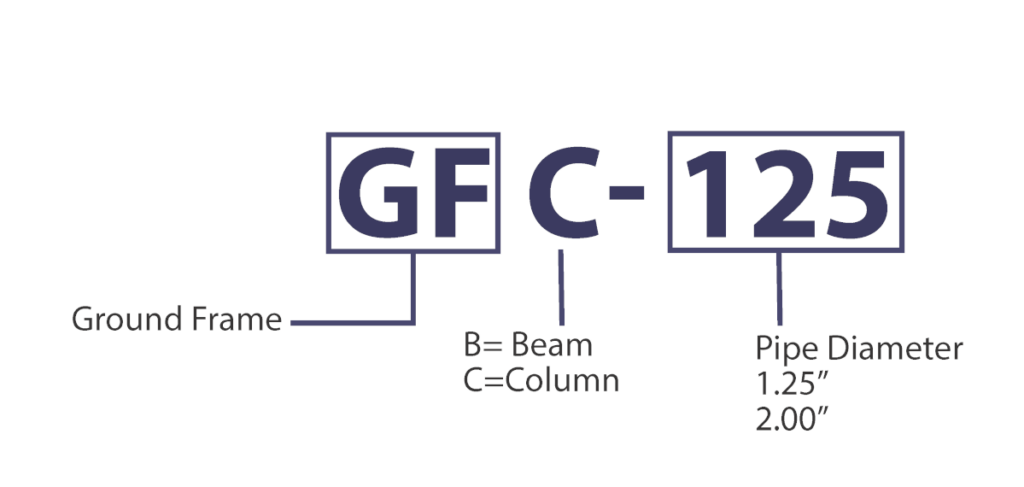

GROUND FRAME SMART PART NUMBERS

Simplify field inventory checks using our smart part numbers.

Required Crew and Tools

Minimum three-person crew for beam installation, two-person for column

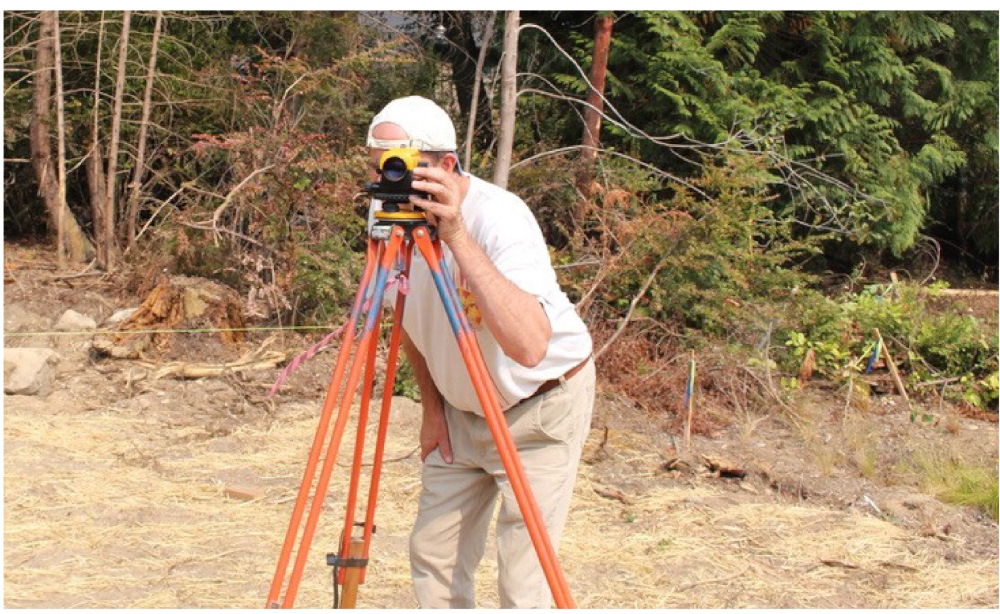

Site transit level

Electric driving hammer (60 or 90 lb) with driving bit

Sledgehammer or post driver

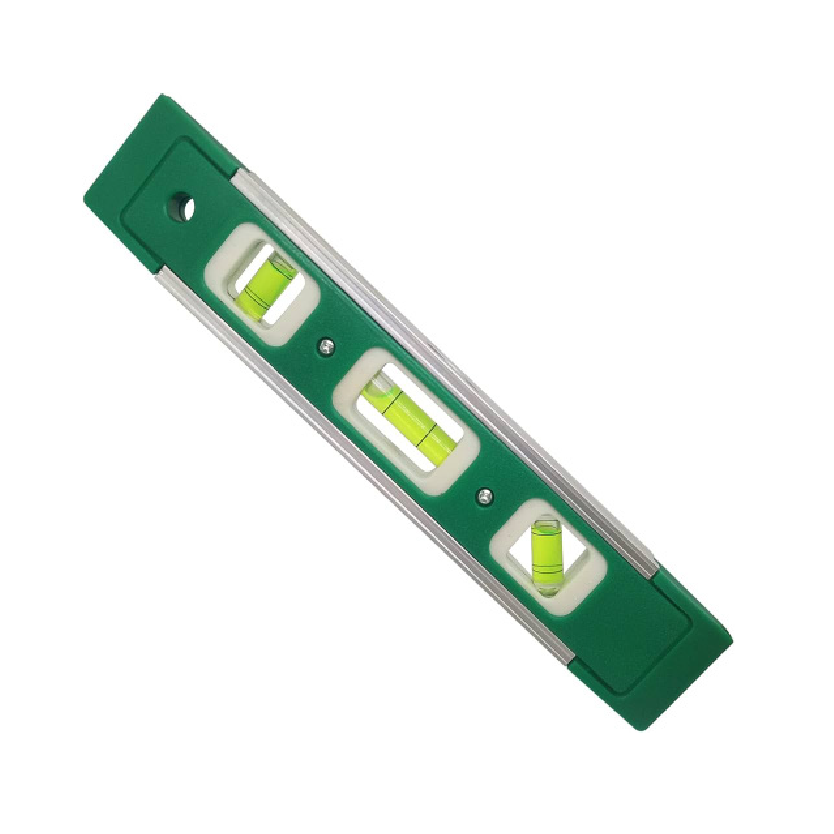

Small level with magnetic edge

Torque wrench, 3-3/4” deep socket, ratcheting wrench, 10” extension

Drill and impact driver

Square-edge shovel required for column installation

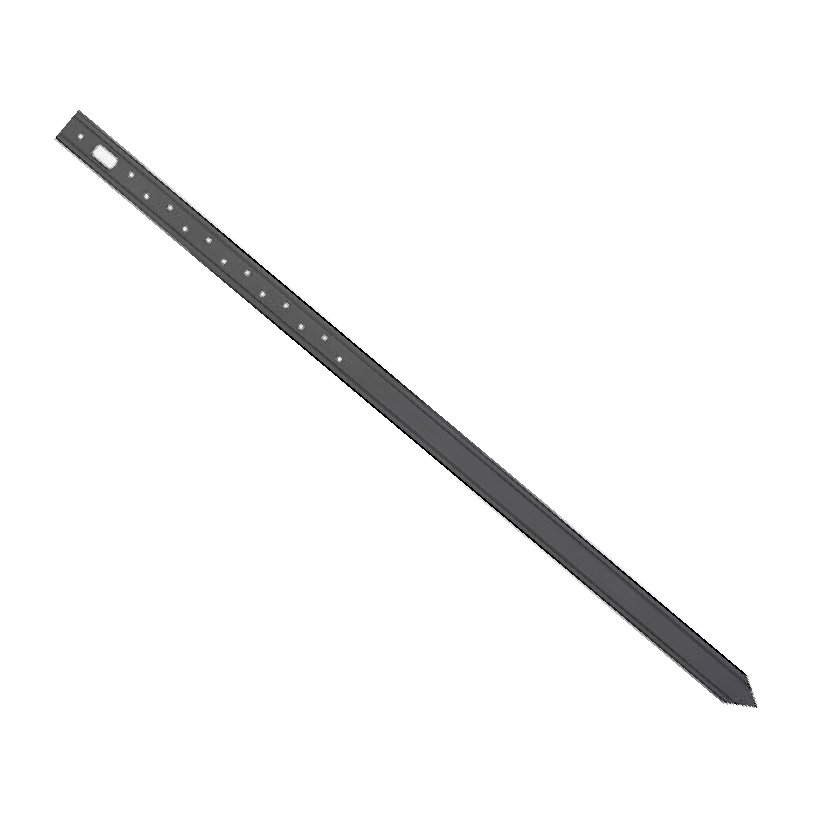

Steel Stake (36″ length)

(Use for batter boards and Ground Frame component alignment, as needed)

2 Pipe Wrenches

2 Pipe Wrenches

(Use heavy duty pipe wrenches that will go over the outside diameter of the pipe)

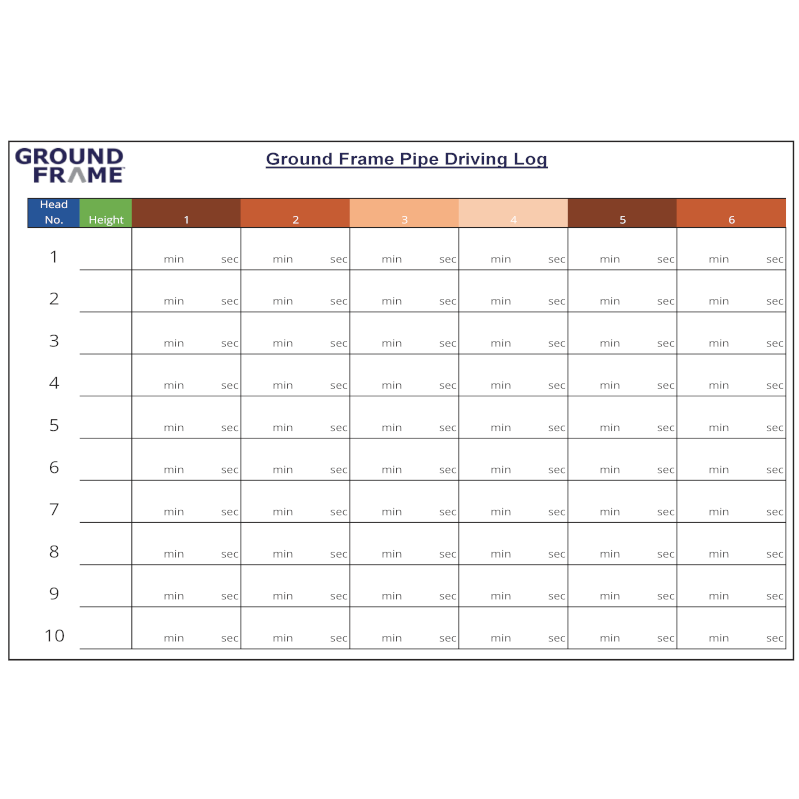

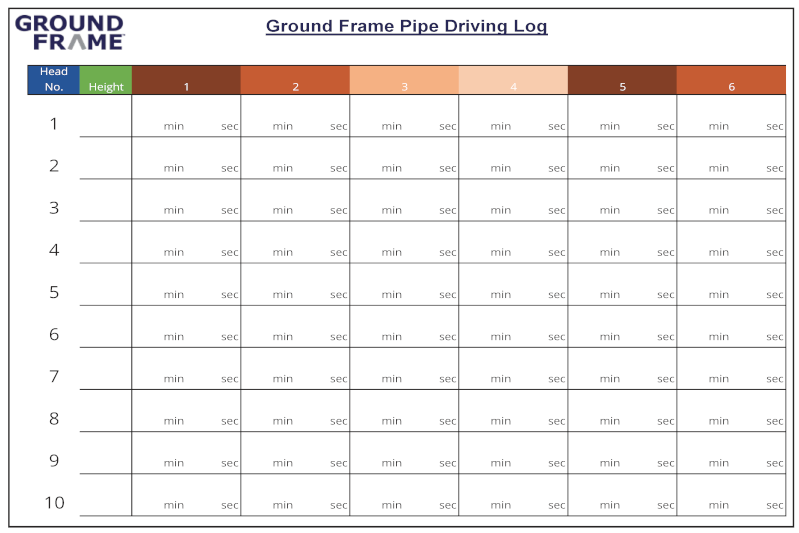

Driving log

Download Driving Log Template

Before You Begin

Check Pipes for Proper Slide

The anchor bolt and force plate are factory set for proper pipe slide, but may have altered during shipping and handling. Pipes should easily slide through holes. If pipes do not easily slide, loosen locking bolt. Do NOT force the pipes through the beam/column holes. If the bolt is fully loosened and the pipes do not easily slide, contact Ground Frame customer service.

| Do | Don’t |

| Follow the instruction in this guide. | Proceed without reading this guide. |

| Check all local building regulations before you begin. | Don’t assume local building regulations have been checked. |

| Use only specified hardware. | Substitute hardware. |

| Review troubleshooting tips to safely remove pipes or adjust pipes. | Force pipes past obstructions. |

Site Preparation

1. Clear and level site as per approved plans. Ensure proper site drainage and desired floor height.

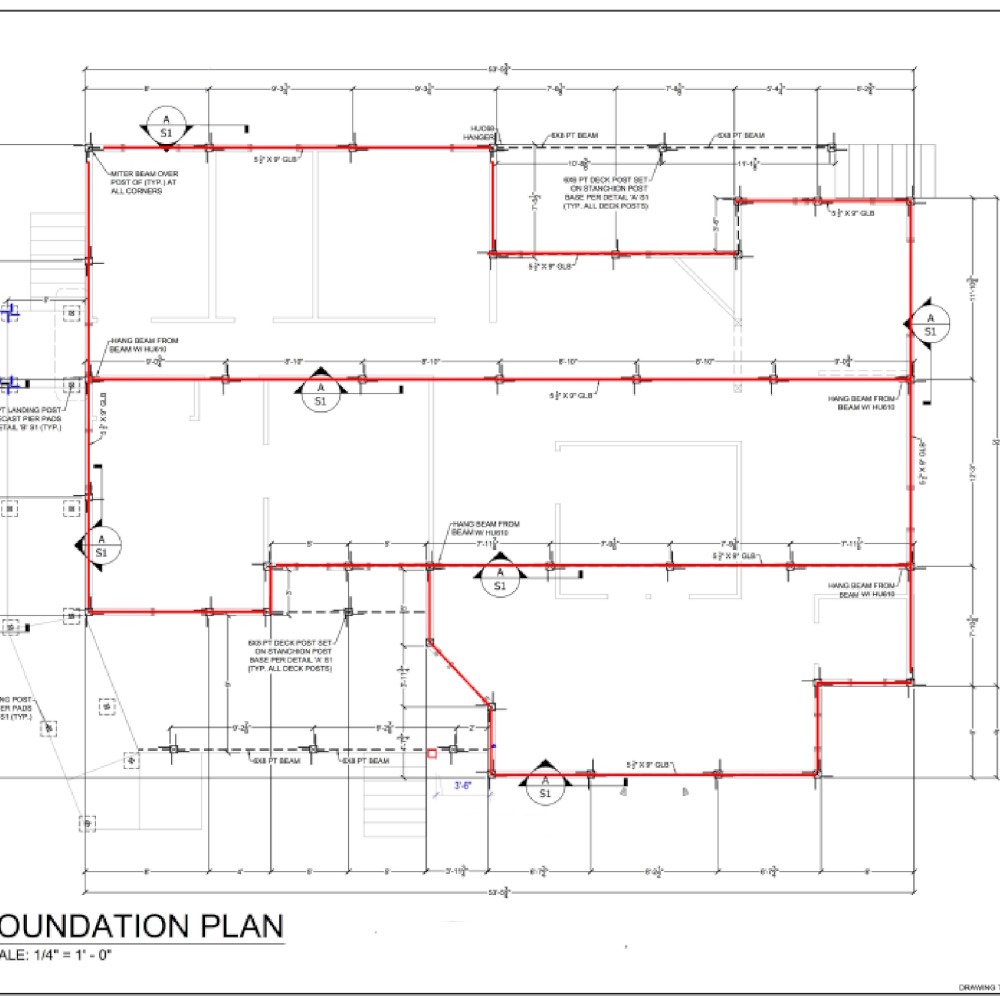

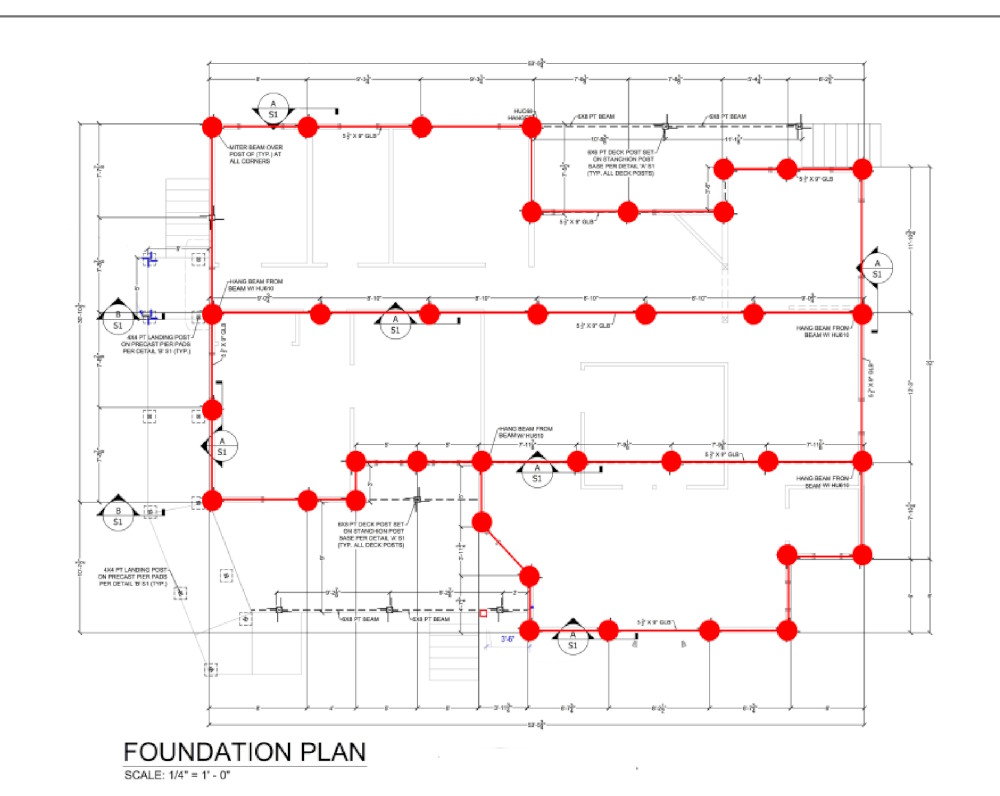

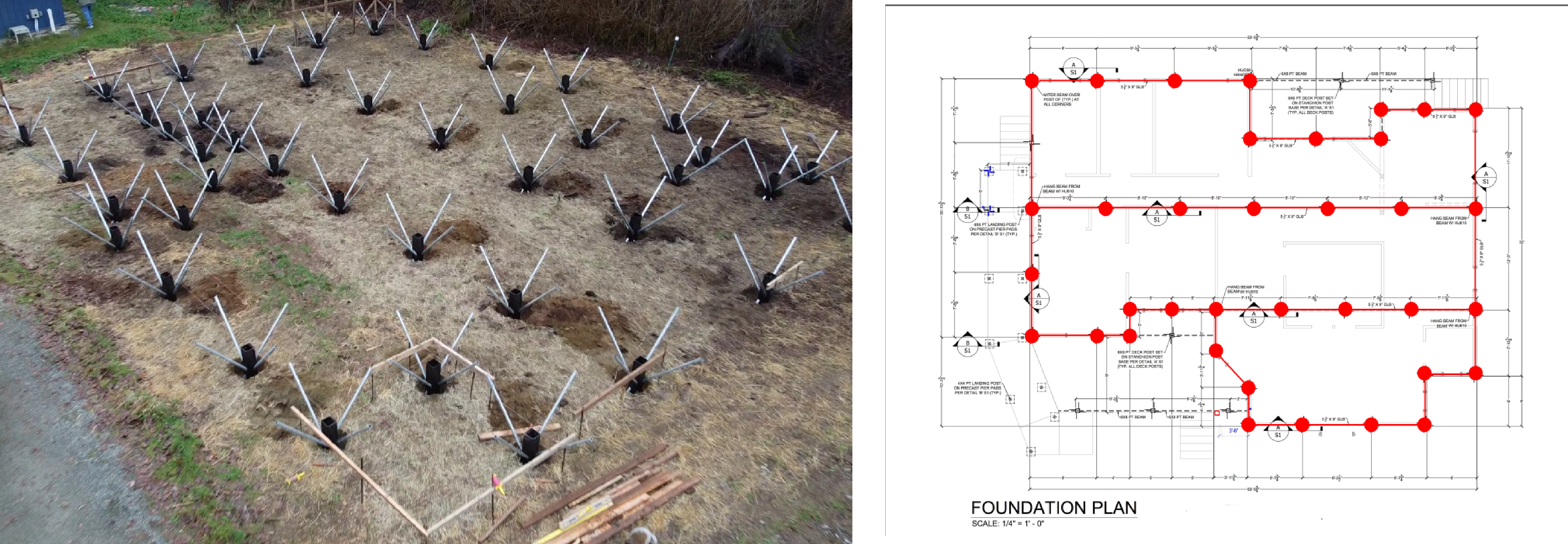

2. Using the dimensioned layout as a guide, establish the building border with a string line.

4. Find the elevation of a “Master Corner” (the highest corner).

5. Using the dimensional layout, roughly stage the Ground Frame columns. It is best practice to start in the corners.

6. Dig a 12”x12” flat bottom square hole large enough to accept column. Compact soil on the bottom of hole for a firm base.

7. Sit columns in hole.

8. Hand set pipes in respective driving holes, approx. 9” deep. Note: Placing pipes immediately after column setting, keeps columns on layout and vertical.

9. Verify all outer dimensions according to the dimensioned layout. Ensure steel columns are plumb, level, and square to the overall layout.

Tip: Using a metal pin inside column to manipulate column until it’s level/plumb. For sloped sites, see addendum below.

Pipe Installation

![]() Ground Frame strongly recommends using a two-person crew for pipe driving, to keep it level and plumb. Ground Frame pipes are not refusal driving systems. All pipes must be driven to their full length to

Ground Frame strongly recommends using a two-person crew for pipe driving, to keep it level and plumb. Ground Frame pipes are not refusal driving systems. All pipes must be driven to their full length to

provide specified bearing, uplift and lateral capacities.

10. If pipe does not easily slide, loosen the nut.

Important Installation Tip: Wrap tape around the first few threads of the anchor bolt to ensure bolt does not fall out of the column.

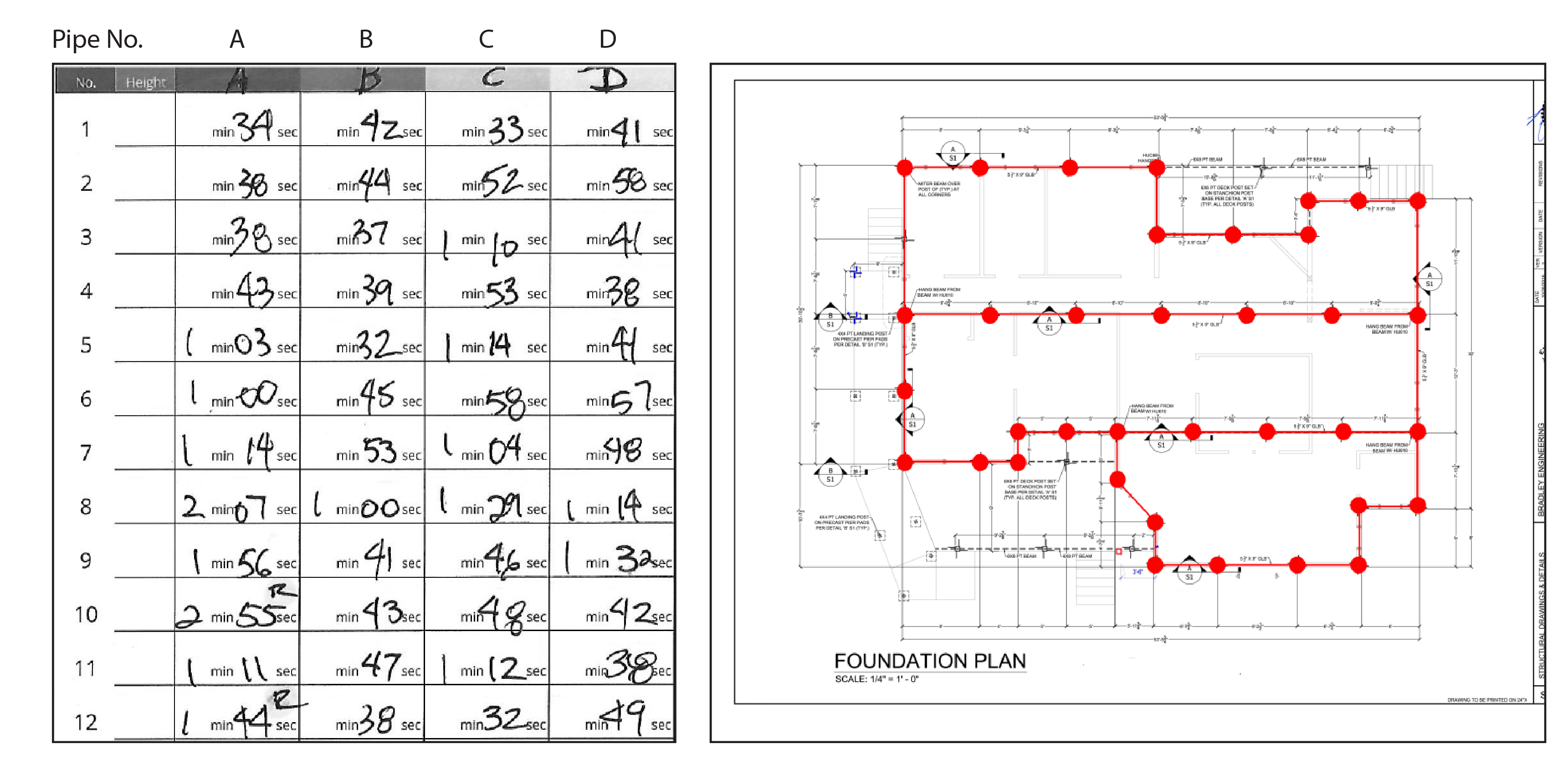

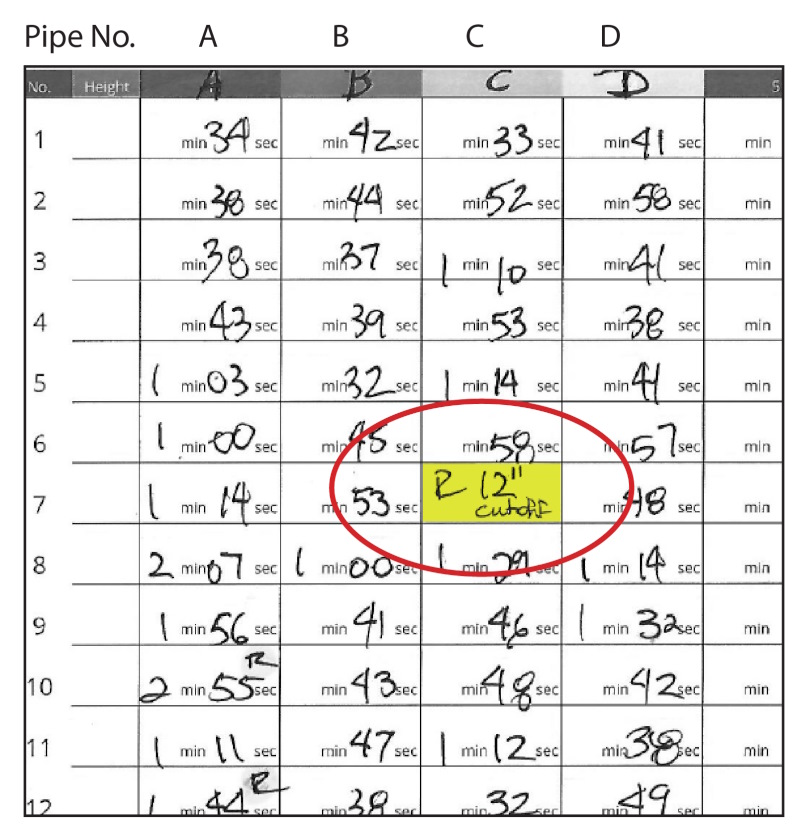

11. Prepare the driving log.

Download Driving Log Template

12. With one person holding the pipe up, drive the pipe through the side driving hole, using the jackhammer with the pipe driving bit.

Tip: The person holding the pipe being driven should also hold the pipe on the opposing side so they can ensure proper pipe angle while simultaneously keeping the column level and plumb.

Note: If, while driving one pipe in, the column begins to tip, move to the opposing pipe and drive it in. Keep track of partial drive times in driving log.

13. Stop driving prior to bit hitting the column.

14. After each pipe installation note time in driving log.

Tip: Take dimensioned layout, number each column, and denote the driving time for each side of the column (A, B, C, D).

15. When pipe hits an obstruction, follow the troubleshooting steps below.

16. Using a 10” x 1/2” drive extension, torque all bolts to 55 ft. lbs.

17. Using a 10” x 1/2” drive extension, torque all bolts to 55 ft. lbs.

18. To determine the floor plane, locate the highest corner.

19. Using a survey stick (recommended), measure from the Stand Off Plate in the highest corner to determine proper post height.

20. Cut posts to required height. Secure posts by screwing in lags. Ensure posts are plumb, level and on string to ensure a level floor plane.

Installation Note: Posts will not always be the same height depending on slope. See addendum below.

21. Install pipe caps on top of each pipe.

Troubleshooting

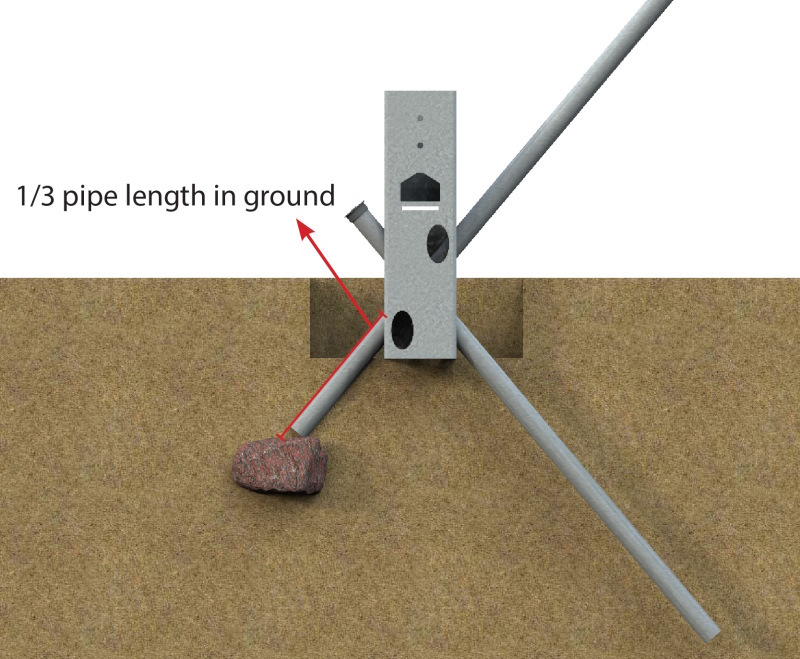

SHALLOW OBSTRUCTION: ~1/3 Pipe Length in the Ground

1. Remove pipe.

Tip: Simultaneously spin and pry pipe, using two pipe wrenches with two people.

2. Remove obstruction and recompact soil in 6” lifts.

3. Redrive pipe.

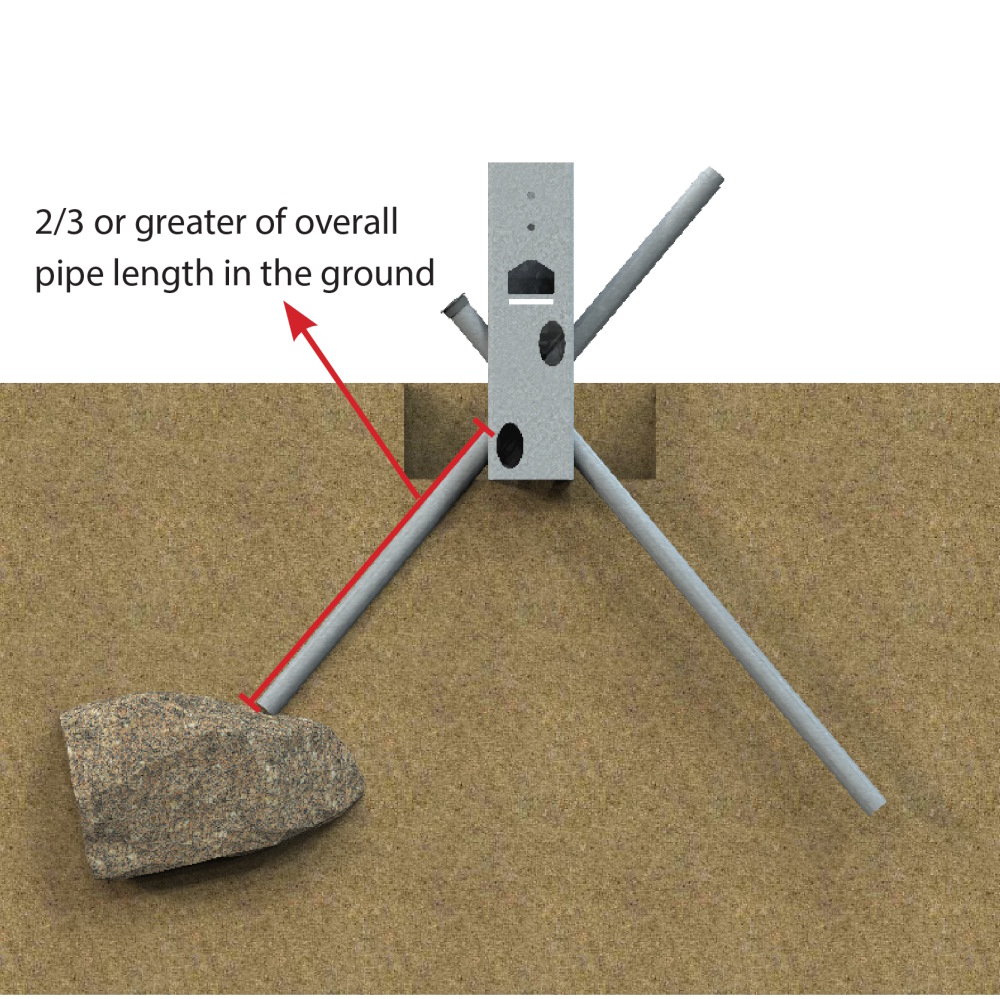

Deep Obstruction: 2/3 Pipe Length in the Ground

1. Using a sledgehammer, strike the pipe, 3-5 blows, to ensure pipe refusal.

2. Cut the remaining portion of the pipe, above the Ground Frame beam, and cap. Important Note: Indicate the length of the pipe that was cut off in the driving log.

Denote refusal (R) and indicate length of pipe that was cut.

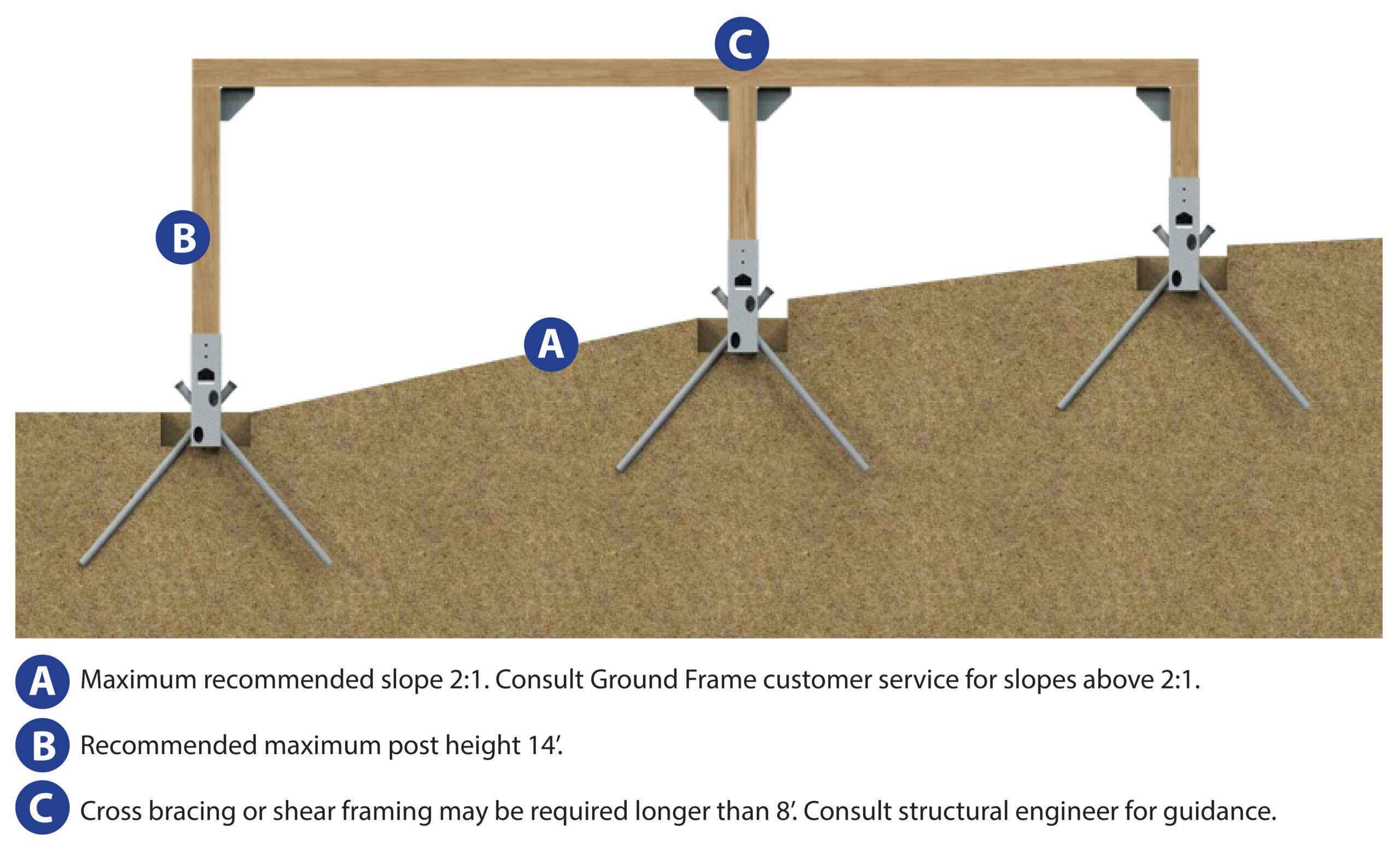

Steep Slope Addendum

Sloped lot with Ground Frame Columns